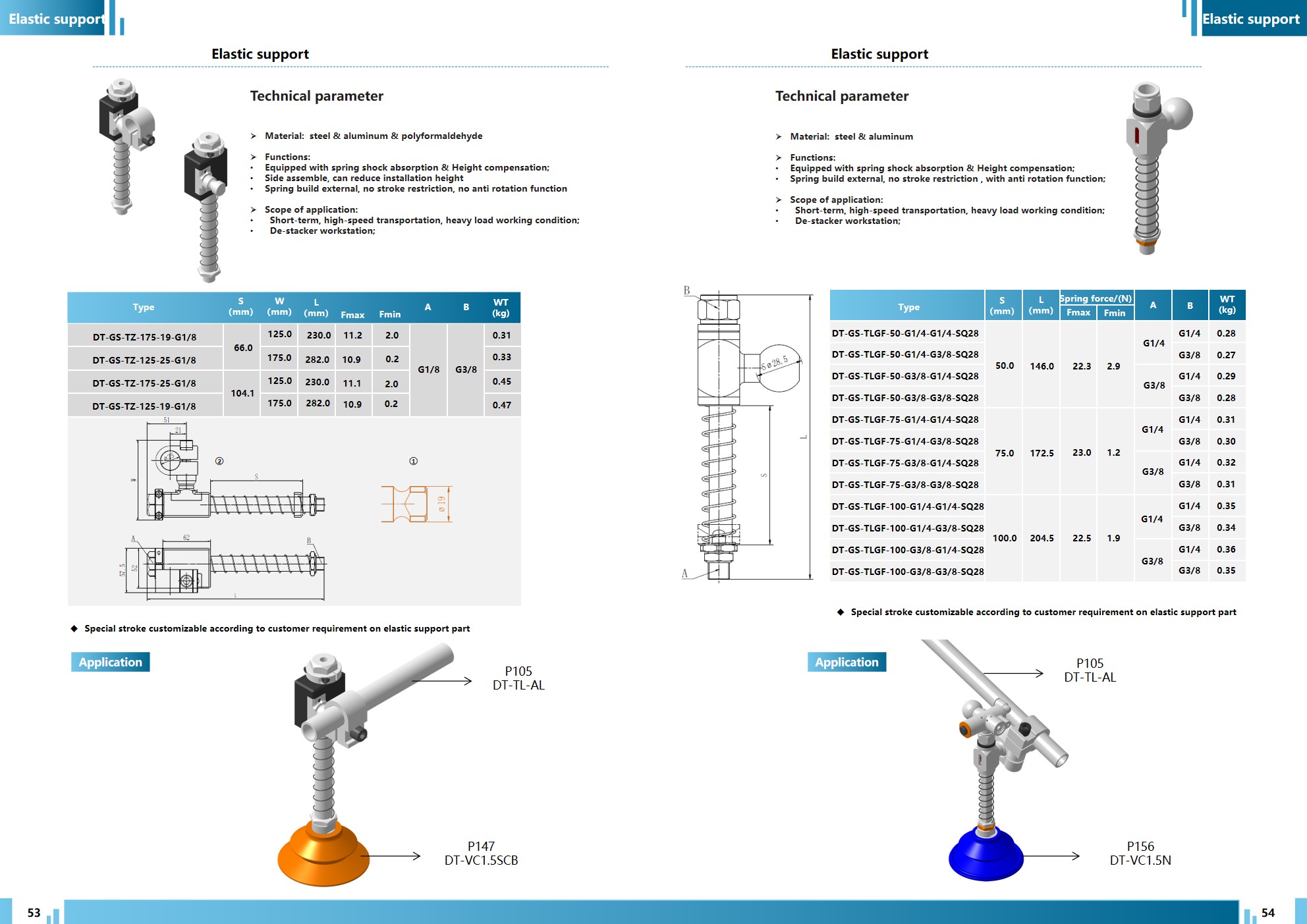

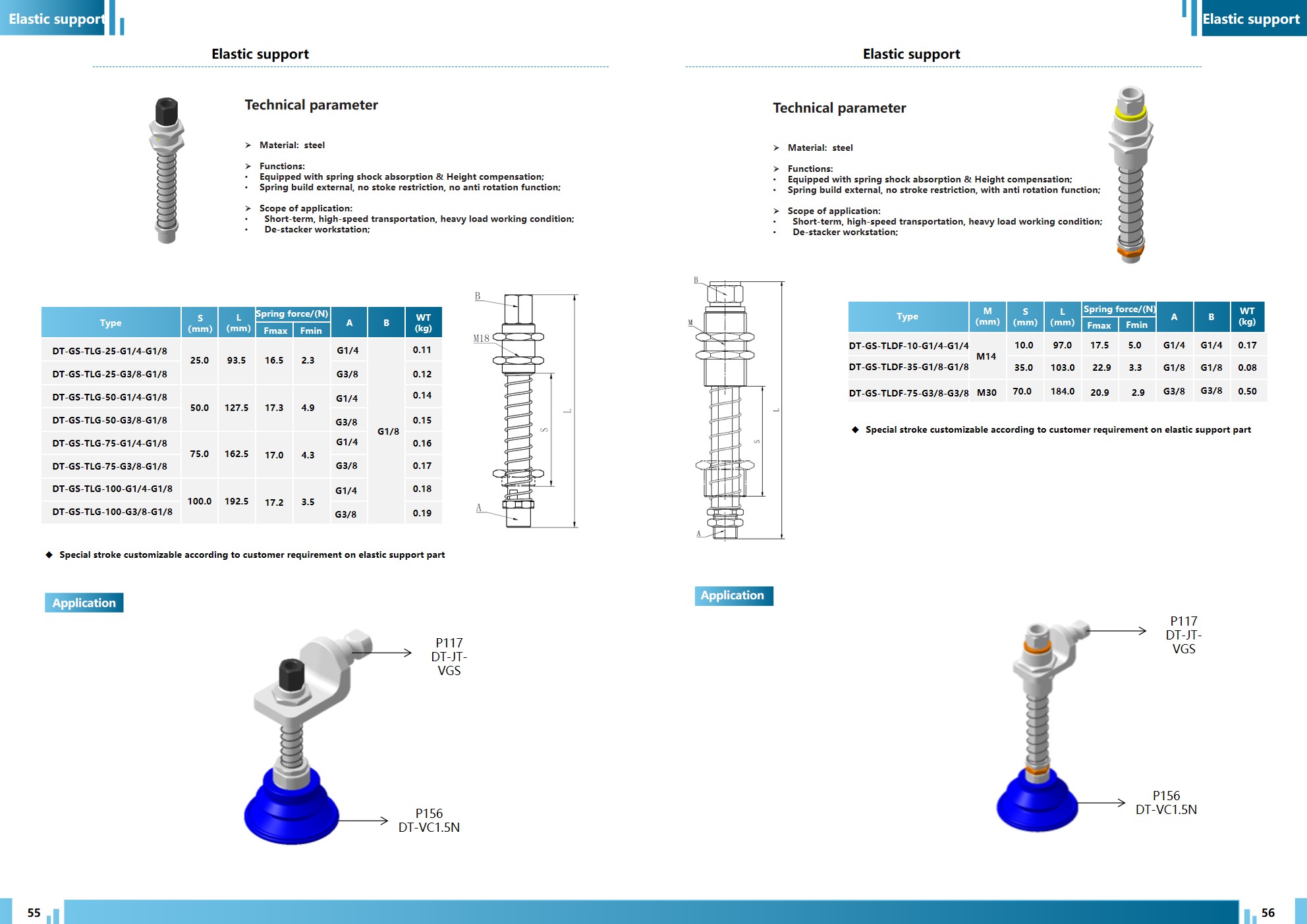

Product Introduction

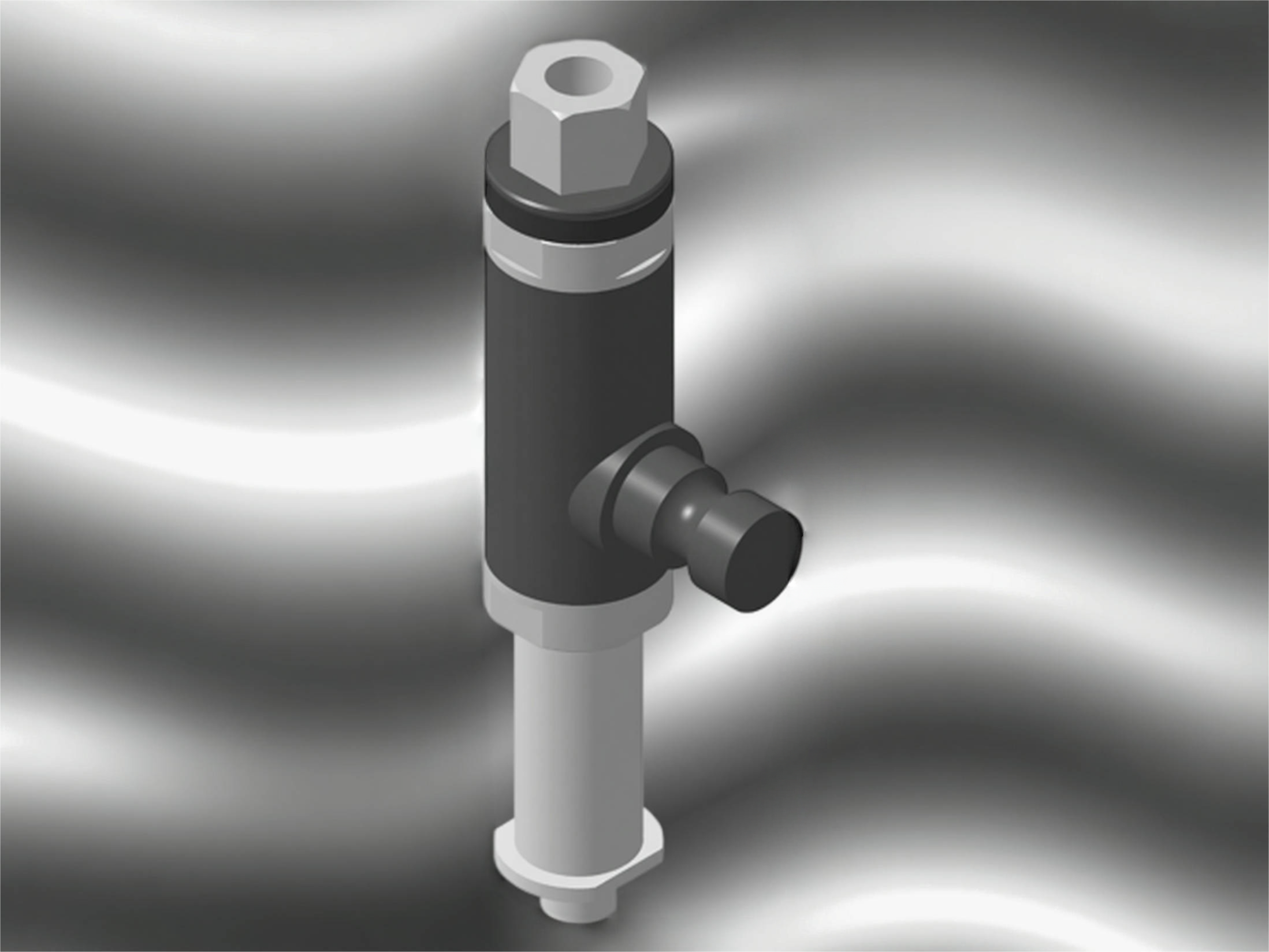

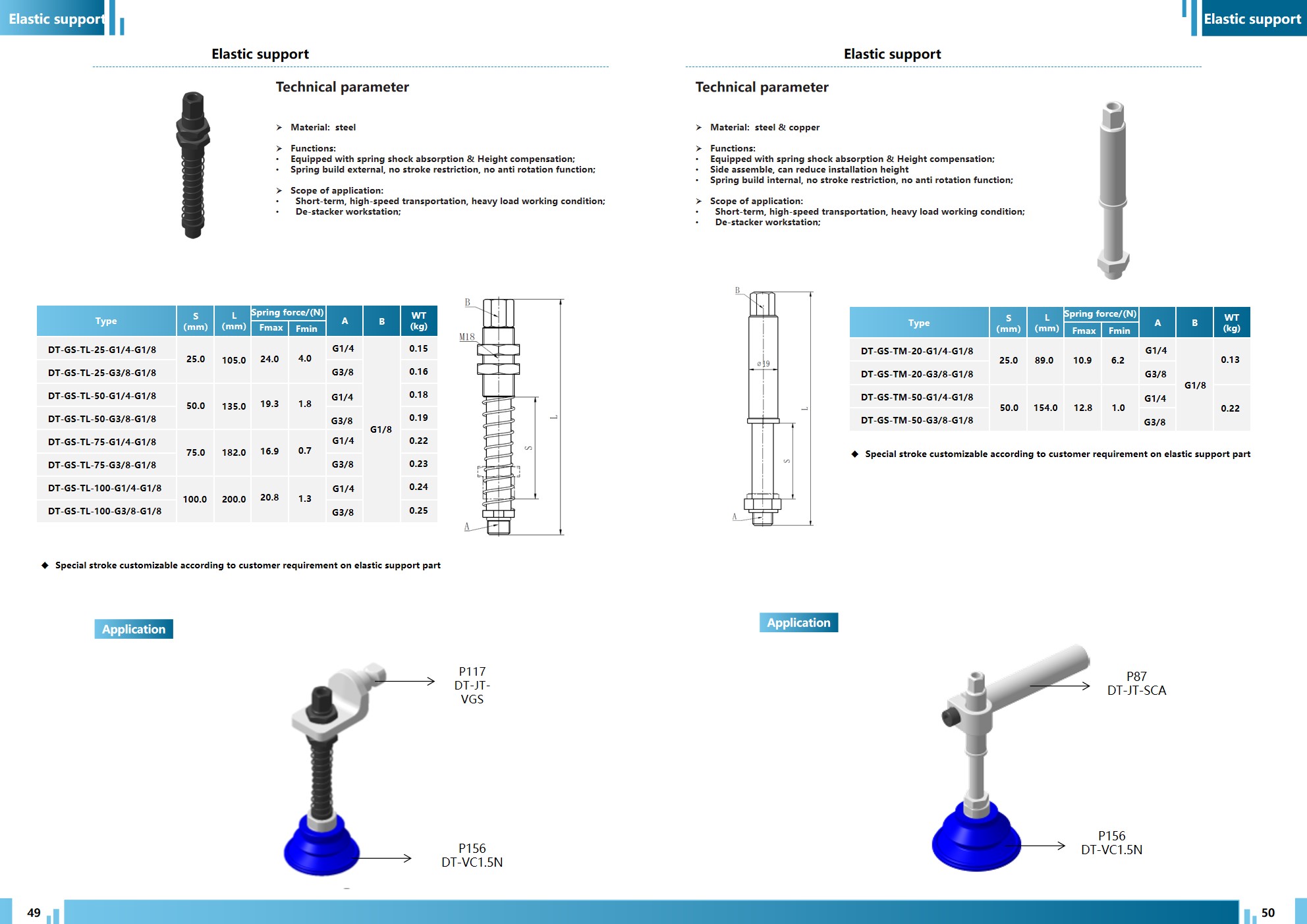

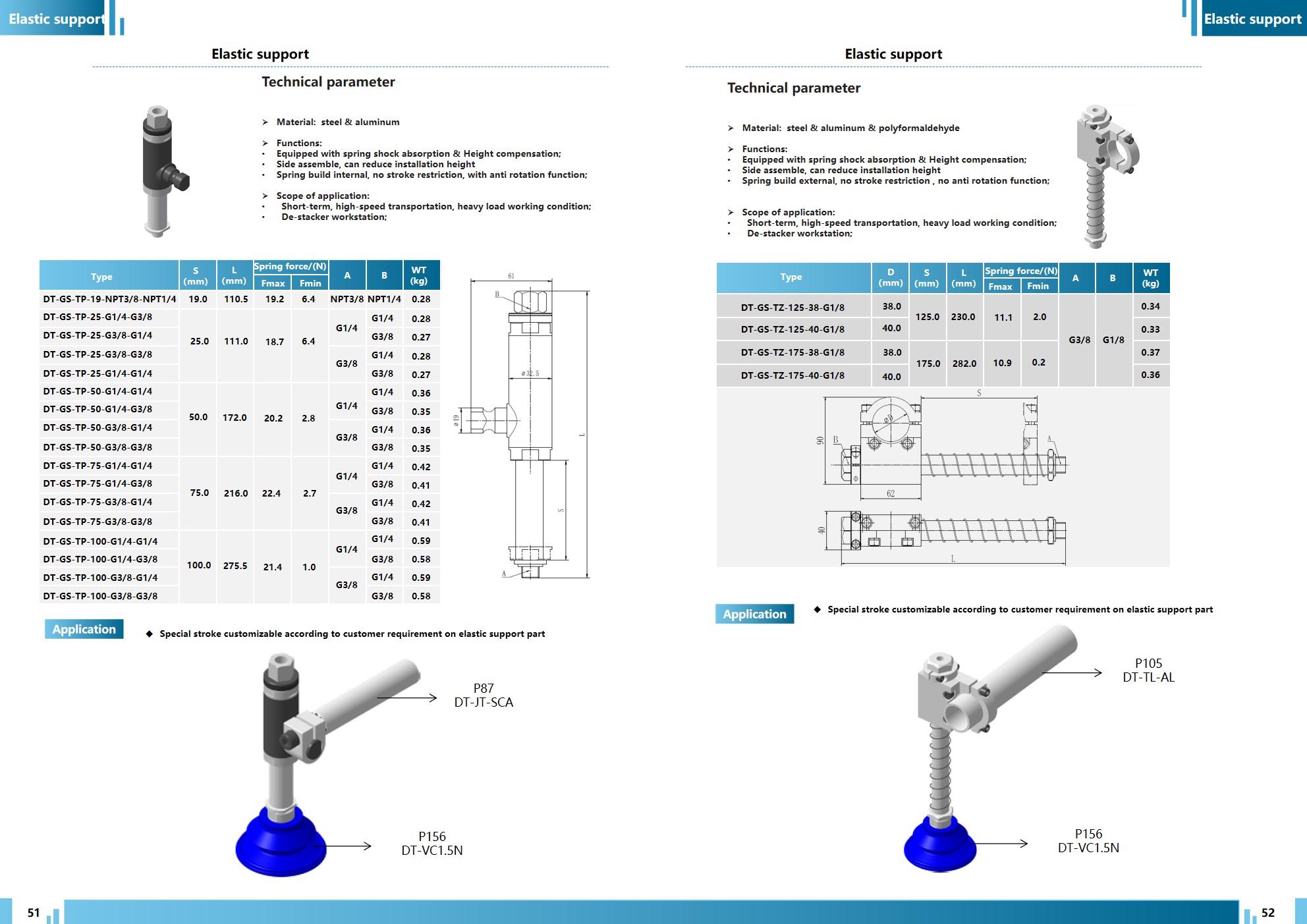

This elastic support is made of steel and features strong spring shock absorption and height compensation functions. The spring has a travel limit and no static rotational energy, making it suitable for heavy-duty conditions with short cycles and short platforms.