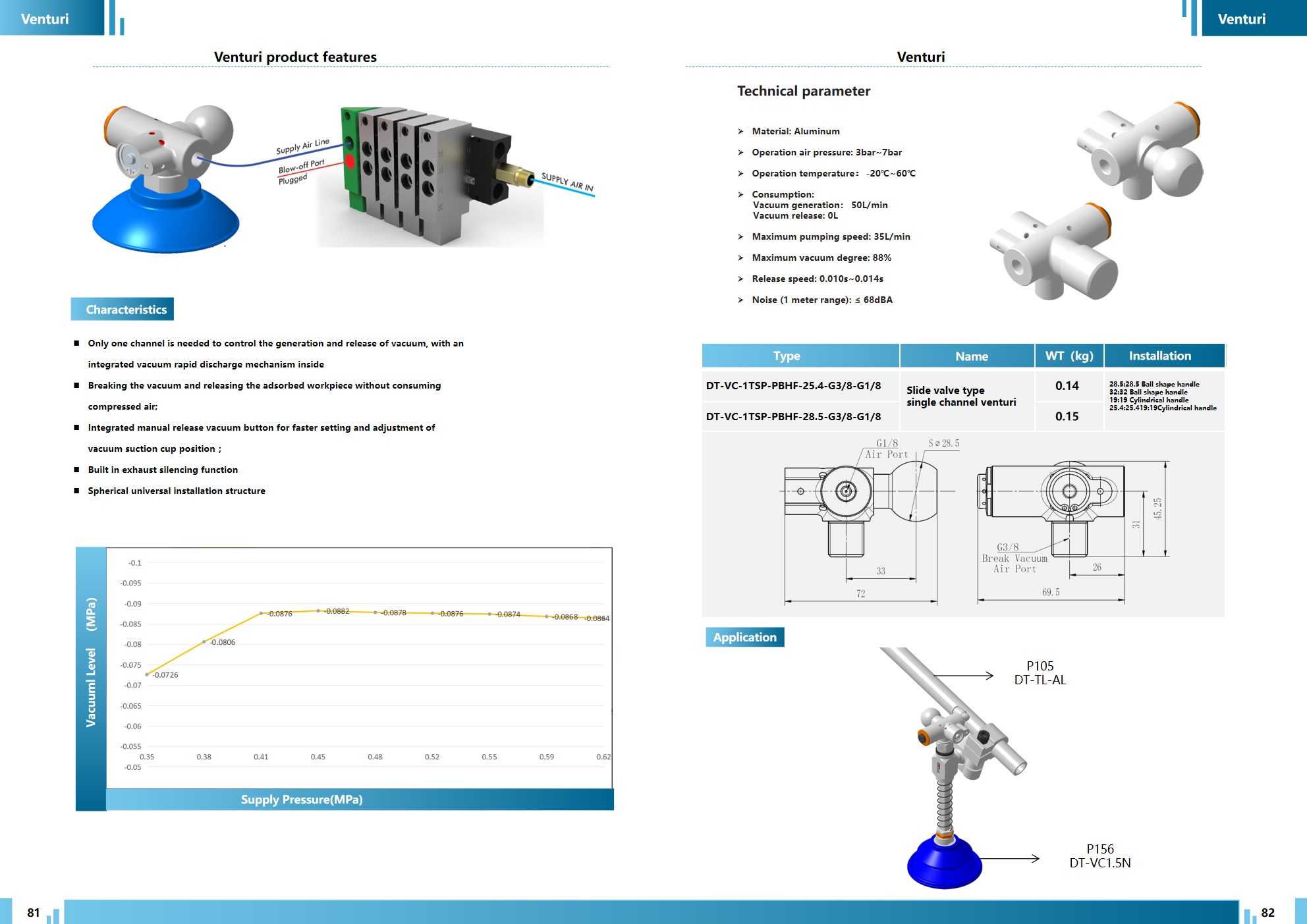

Product Features

- Only one channel is required to control vacuum generation and release, with an internal integrated rapid vacuum release mechanism.

- When breaking the vacuum and releasing the adsorbed workpiece, no compressed air is consumed.

- Integrated manual vacuum release button allows for faster setup and adjustment of vacuum cup position.

- Built-in exhaust silencer function.

- Spherical universal joint mounting structure.