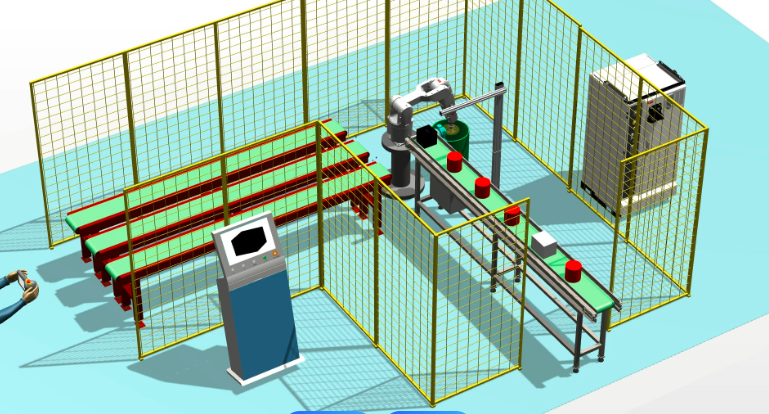

We are technically advanced in product assembly and debugging. The company employs advanced processes and high-precision equipment to accurately assemble each component and strictly calibrate them, ensuring that product performance and quality meet industry standards and customer requirements. Meanwhile, we offer offline physical simulation services. With the help of professional simulation software and equipment, we conduct simulation and analysis of the assembly process and operational status, identify potential problems in advance, optimize solutions, reduce on-site debugging time and costs, and efficiently deliver high-quality automation equipment solutions.