SERVICE

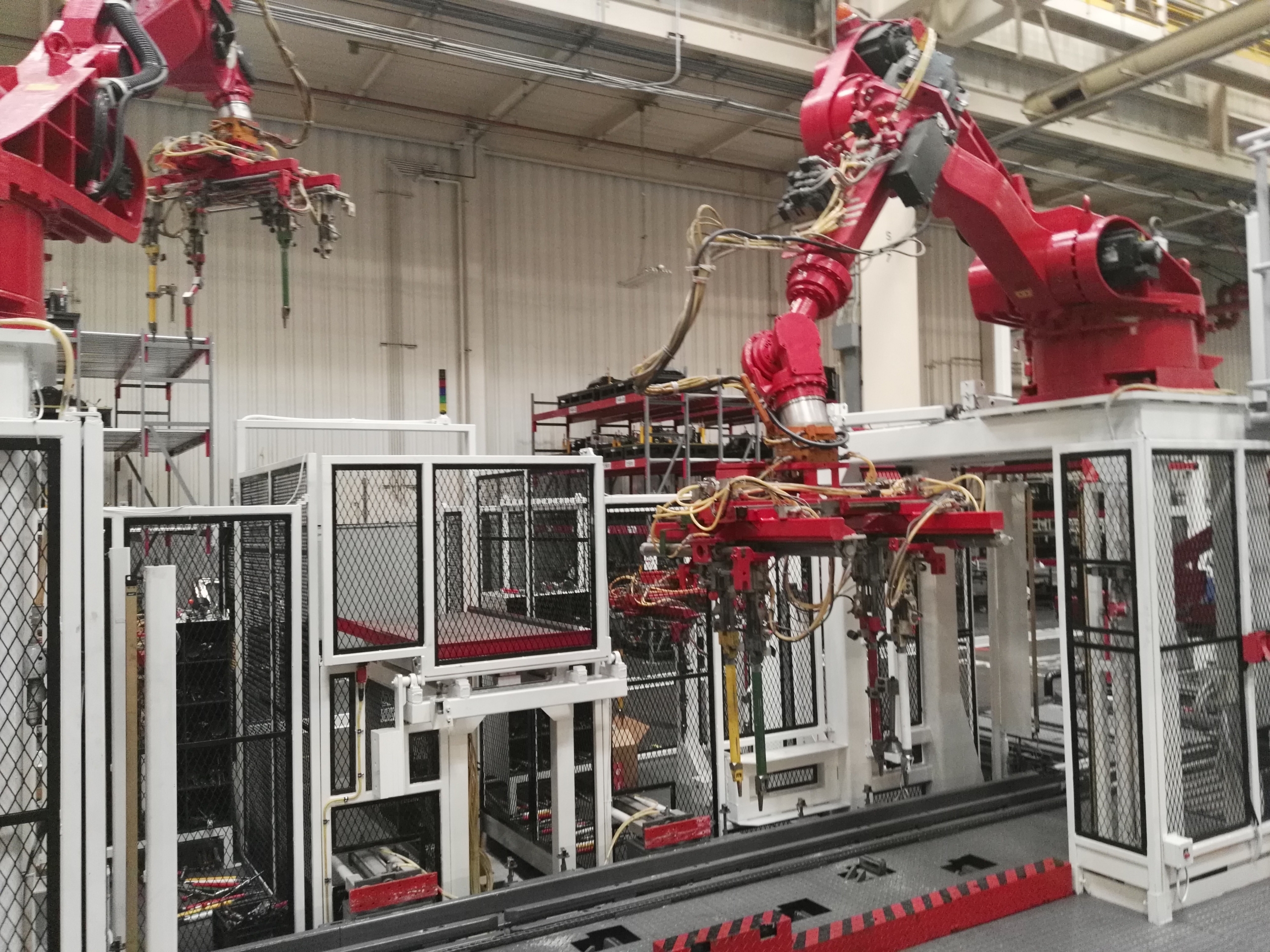

We offer full-chain automation services. Focusing on fields such as automotive intelligent manufacturing and new energy automation, we rely on our professional technical team to provide customized non-standard services. From initial demand research and solution design to the design and manufacturing of automation equipment, we pay attention to every detail to ensure excellent equipment performance and reliable quality. In the later stages, we provide efficient installation and debugging services and have established a 7×24-hour after-sales response system to safeguard the stable operation of the equipment, helping enterprises improve production efficiency and achieve intelligent upgrades.