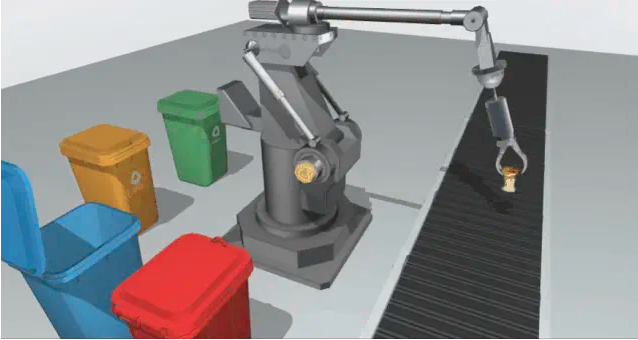

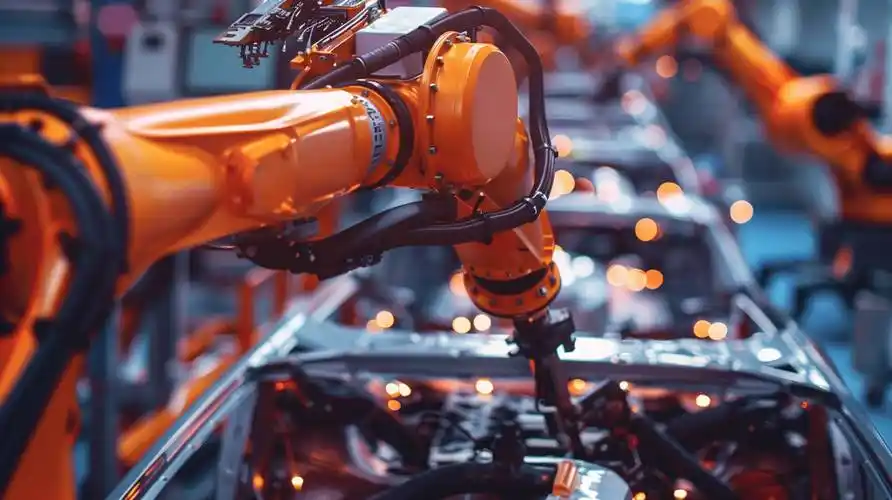

Our engineering design team specializes in the design of non-standard automated equipment. In the early stages of design, we conduct in-depth research into the market and customer needs. We use software such as CAD and SolidWorks for 3D modeling to comprehensively design mechanical structures. We utilize dynamic simulation modeling to verify feasibility and stability, while also considering operability, maintainability, and cost control. We deliver high-performance, reliable, and cost-effective design solutions to our customers.