This product, specially designed for industrial scenarios, is made from a combination of aluminum, steel, and permanent magnets. It operates in a temperature range of -20℃ to 180℃ and a pressure range of 3 bar to 7 bar, making it suitable for complex working conditions. It features a built-in high-strength permanent magnet for reliable suction, a wear-resistant steel suction cup base, and a rubber ring to prevent scratches. It can maintain suction even during power or air supply interruptions, making it ideal for handling porous steel plates and automotive hot-stamped blanking parts.

Magnetic Cup

- Product Introduction

- Product Features

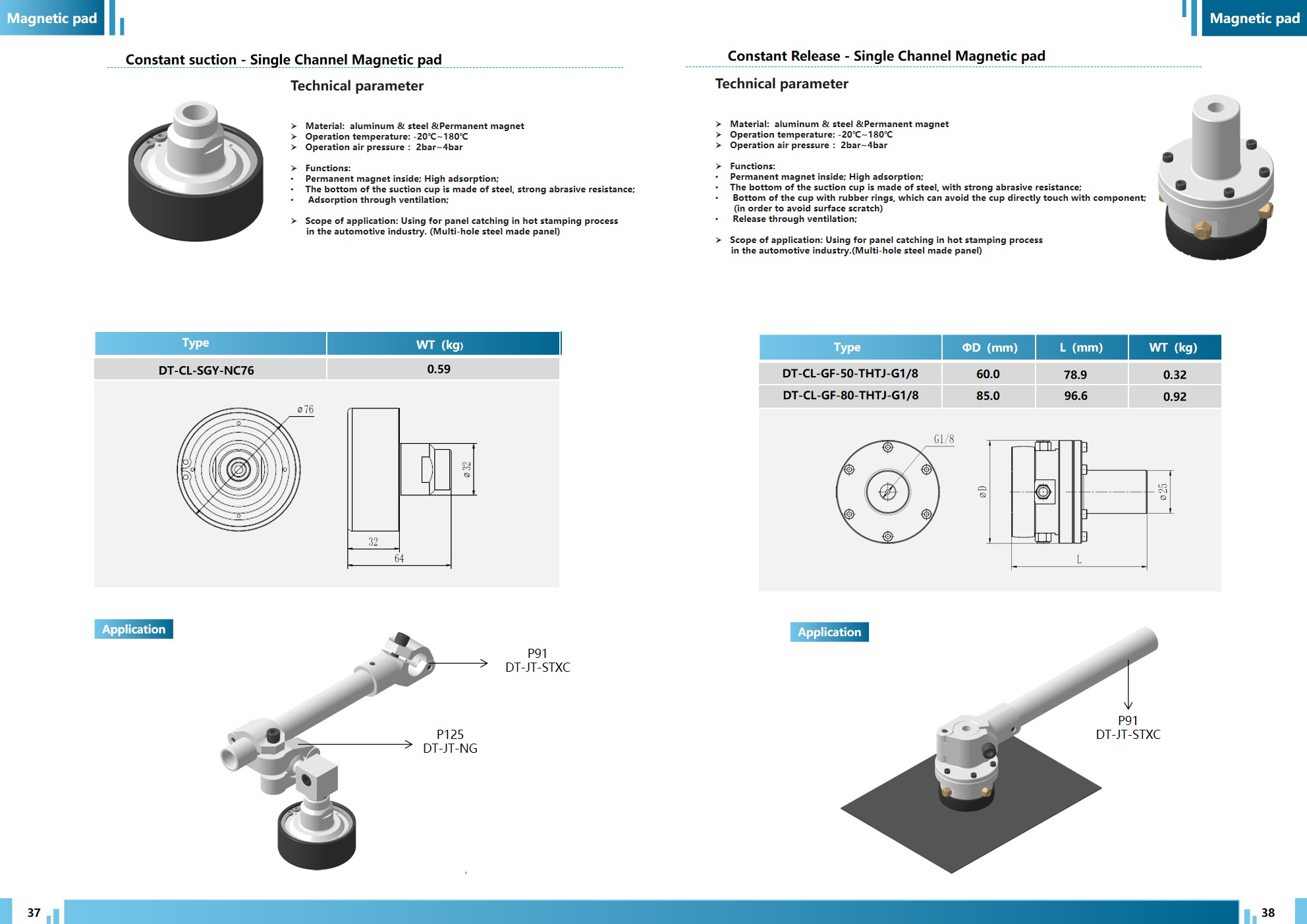

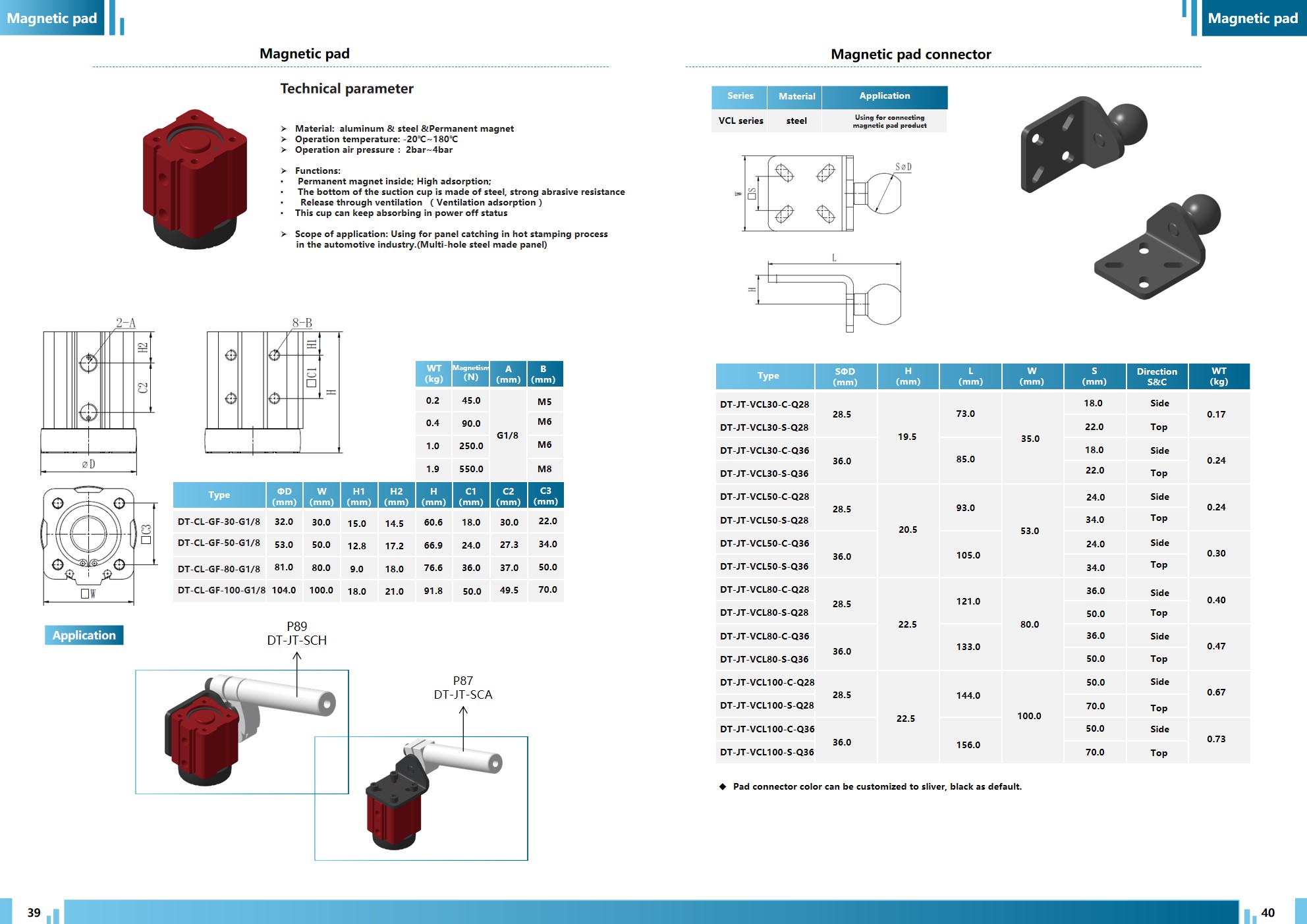

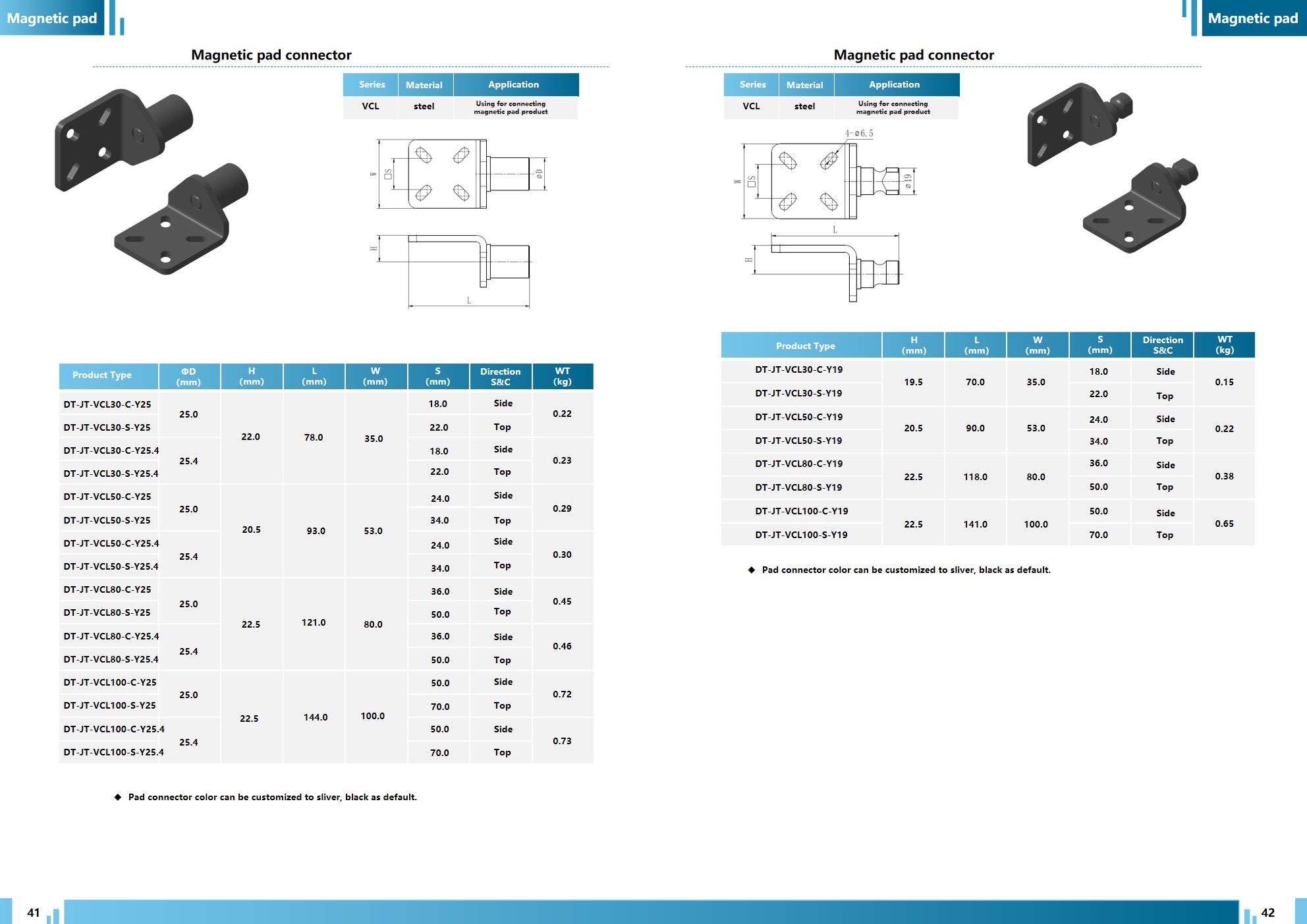

Adopted MaterialsAluminum & Steel & Permanent Magnet

Operating Temperature: -20℃~180℃

Operating Air Pressure:3bar~7bar

Product Functions:① Built-in permanent magnet with high-performance strength, ensuring reliable suction.

② The suction cup base is made of steel, offering strong wear resistance.

③ A rubber ring is installed at the base of the suction cup to prevent direct contact between the suction cup and the parts, which could otherwise cause scratches on the surface of the parts.

④ It remains in the suction state even when power and air supply are cut off.

Scope of Application:Suitable for handling porous steel plates and for the suction of blanking parts in the automotive hot stamping process.

PRODUCT CENTER

Production

Full Information

PRODUCT CENTER

-

Official WeChat Public Platform