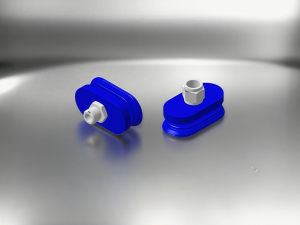

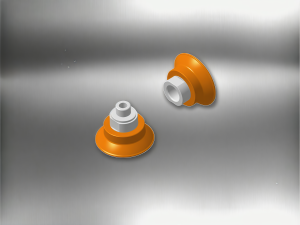

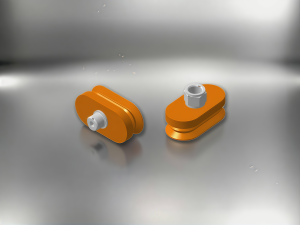

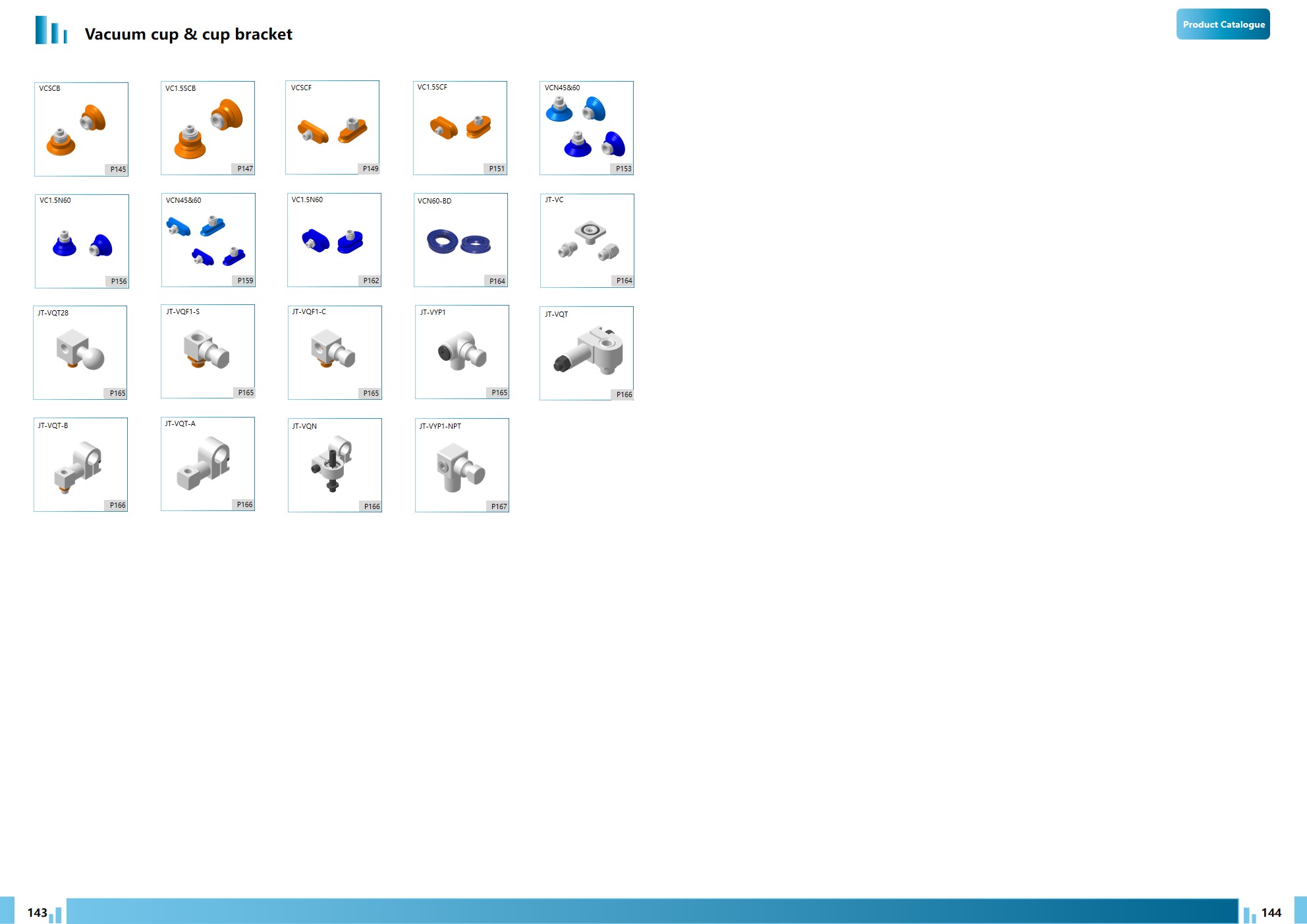

Product Features

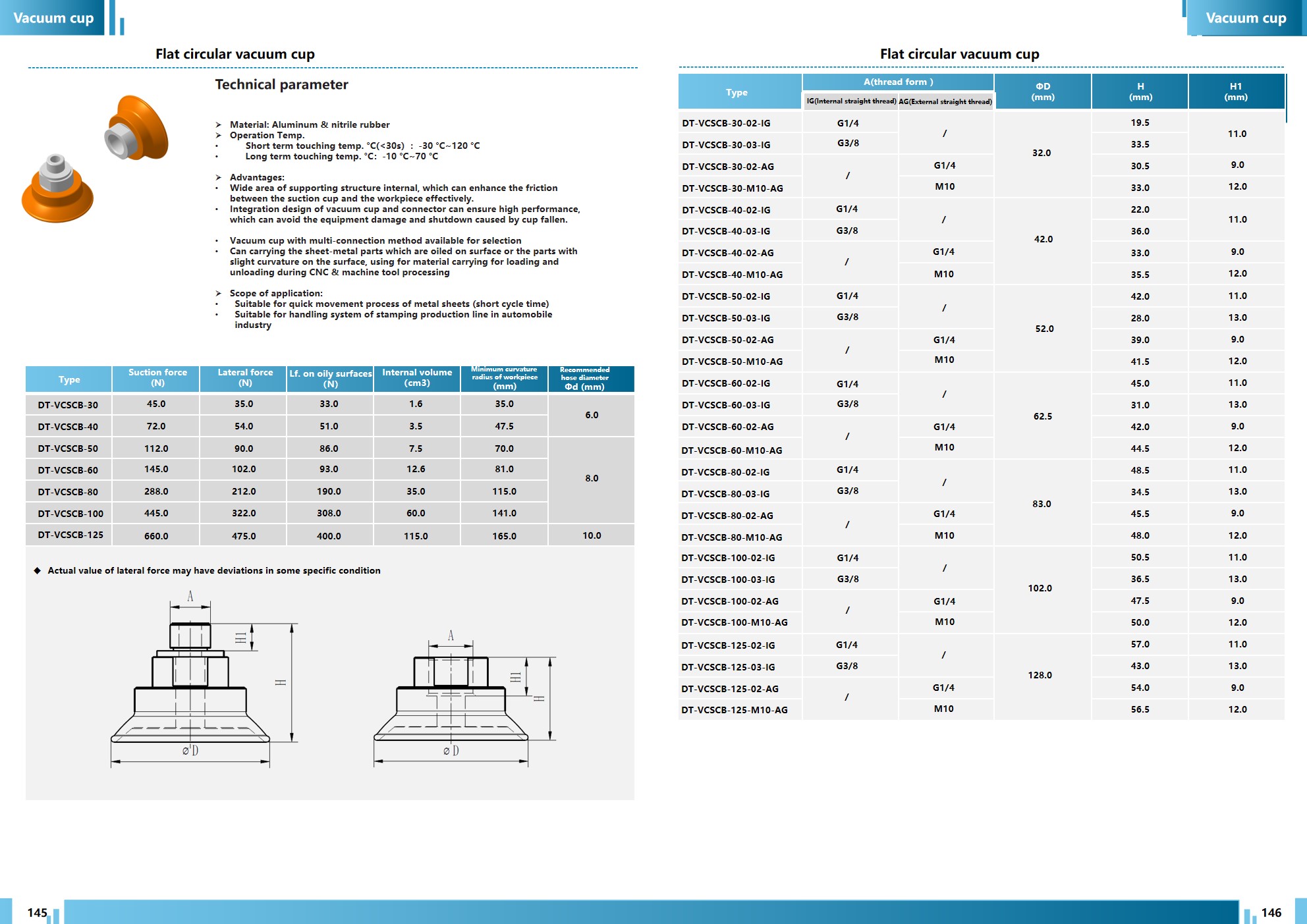

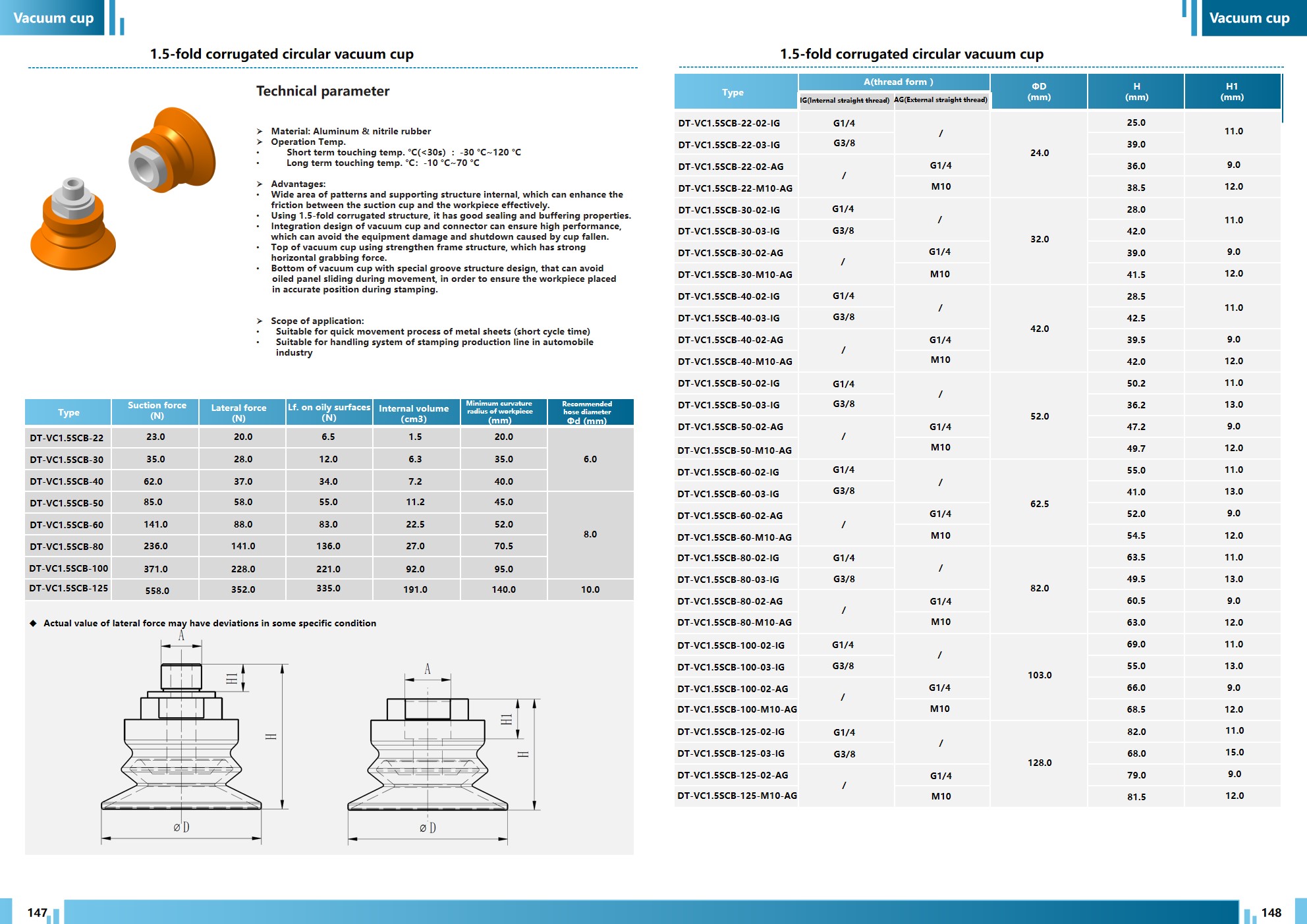

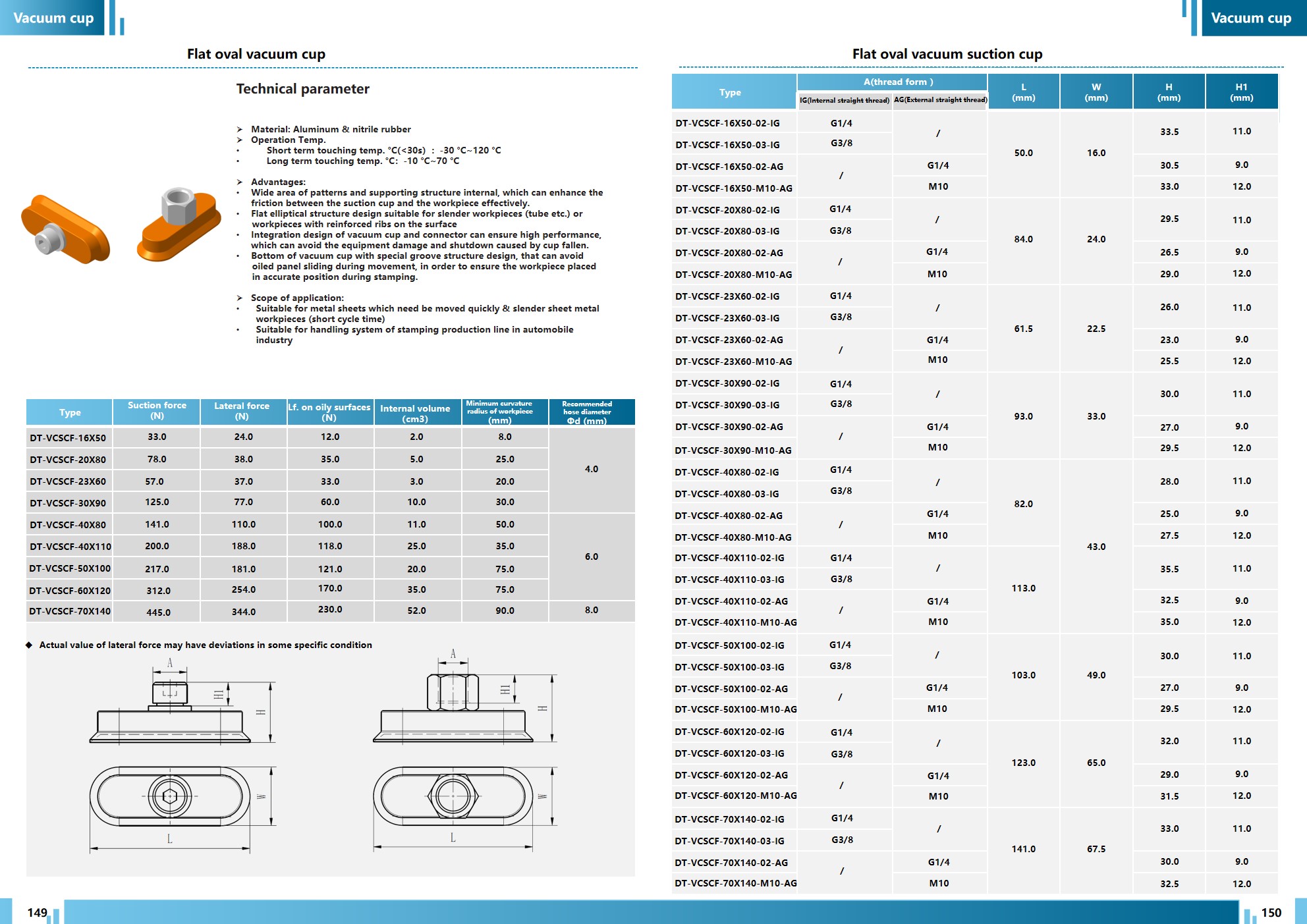

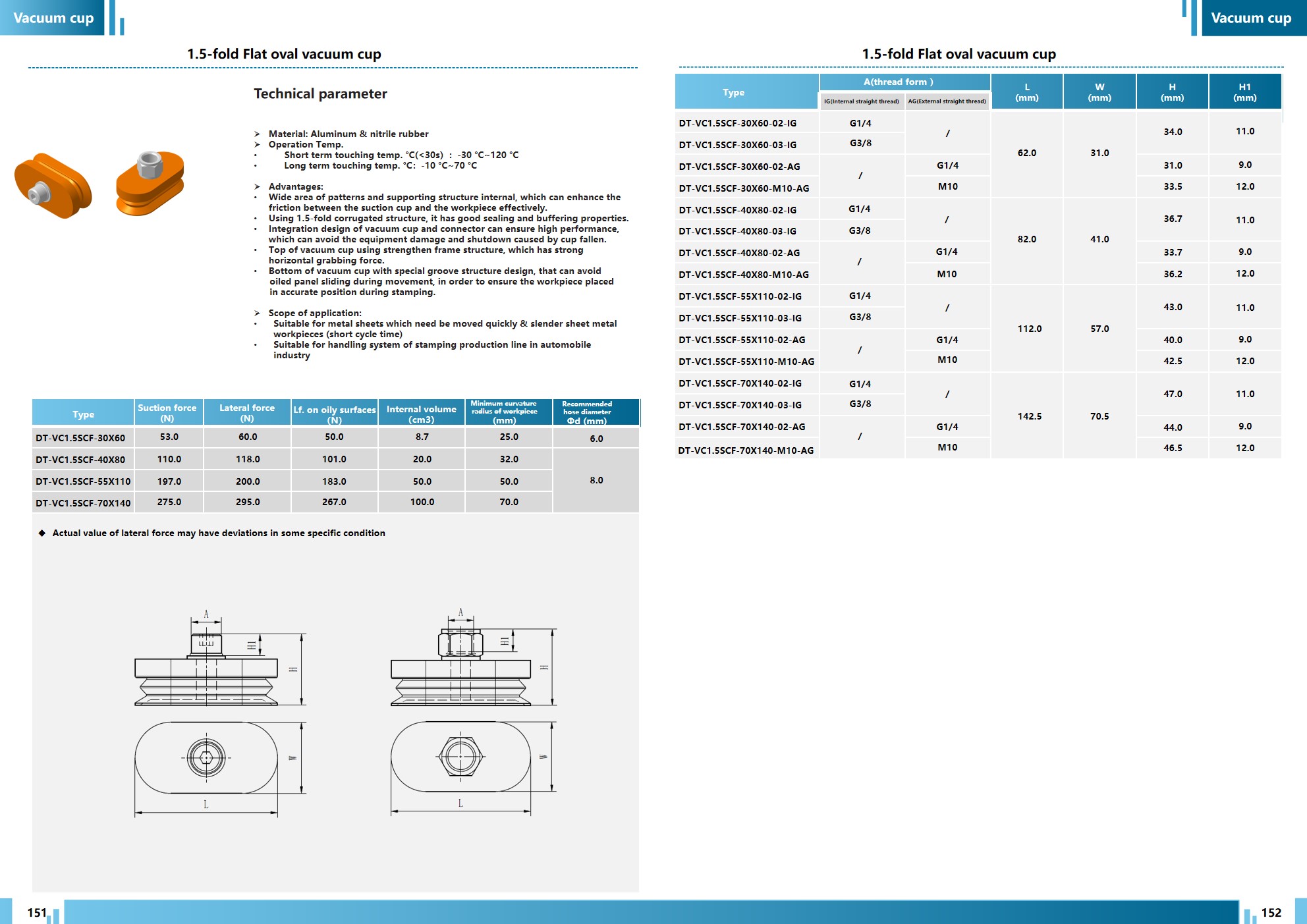

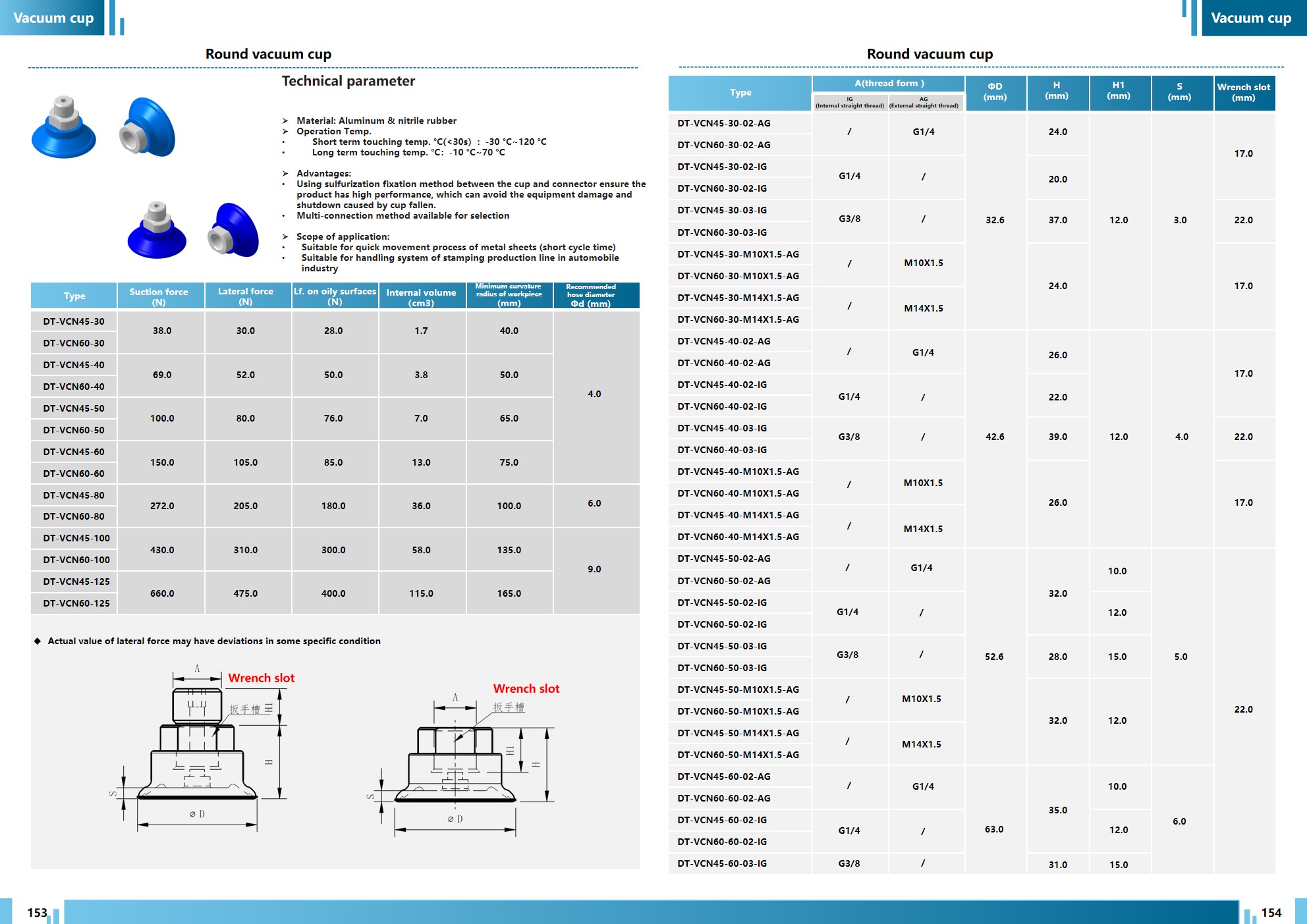

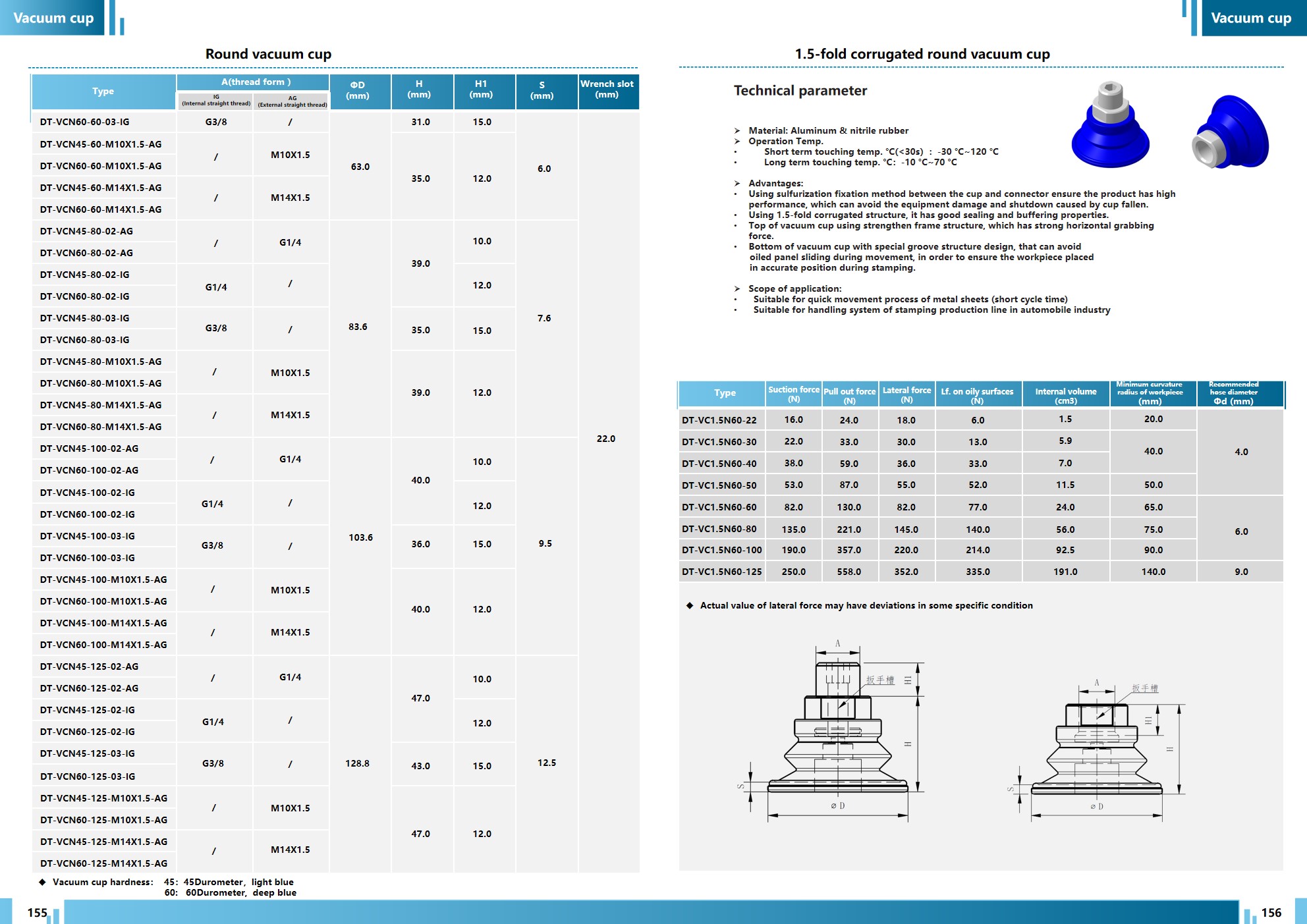

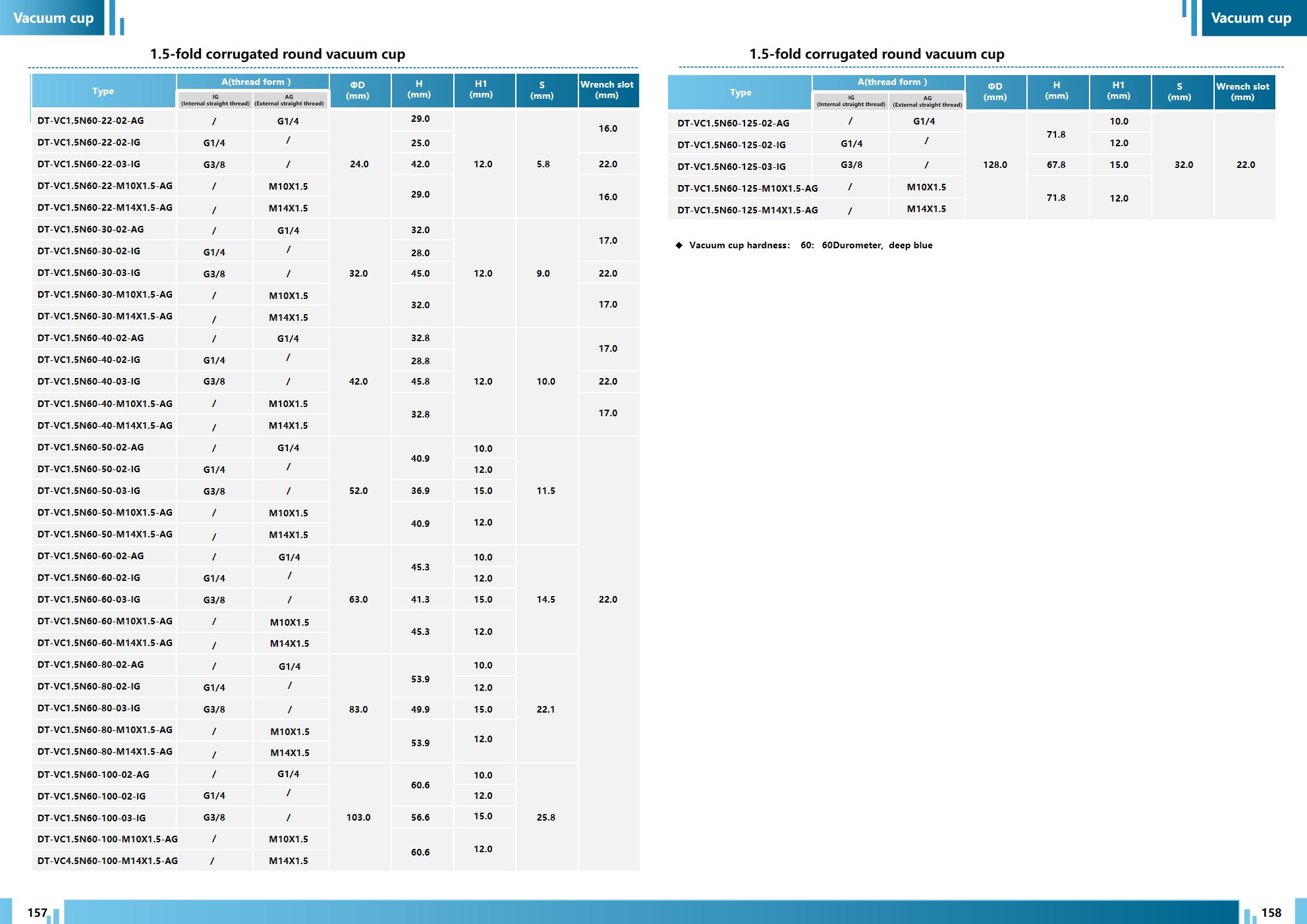

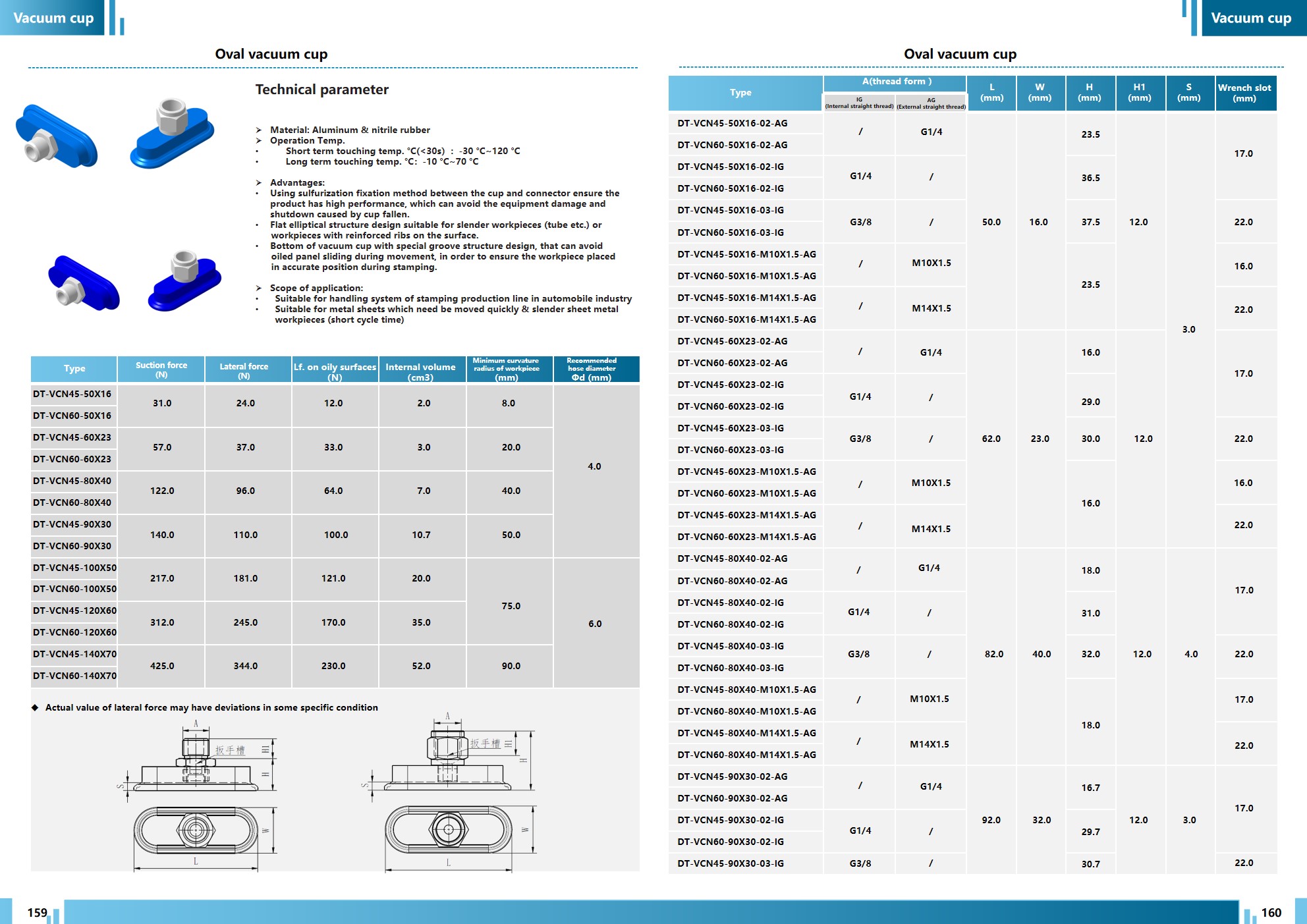

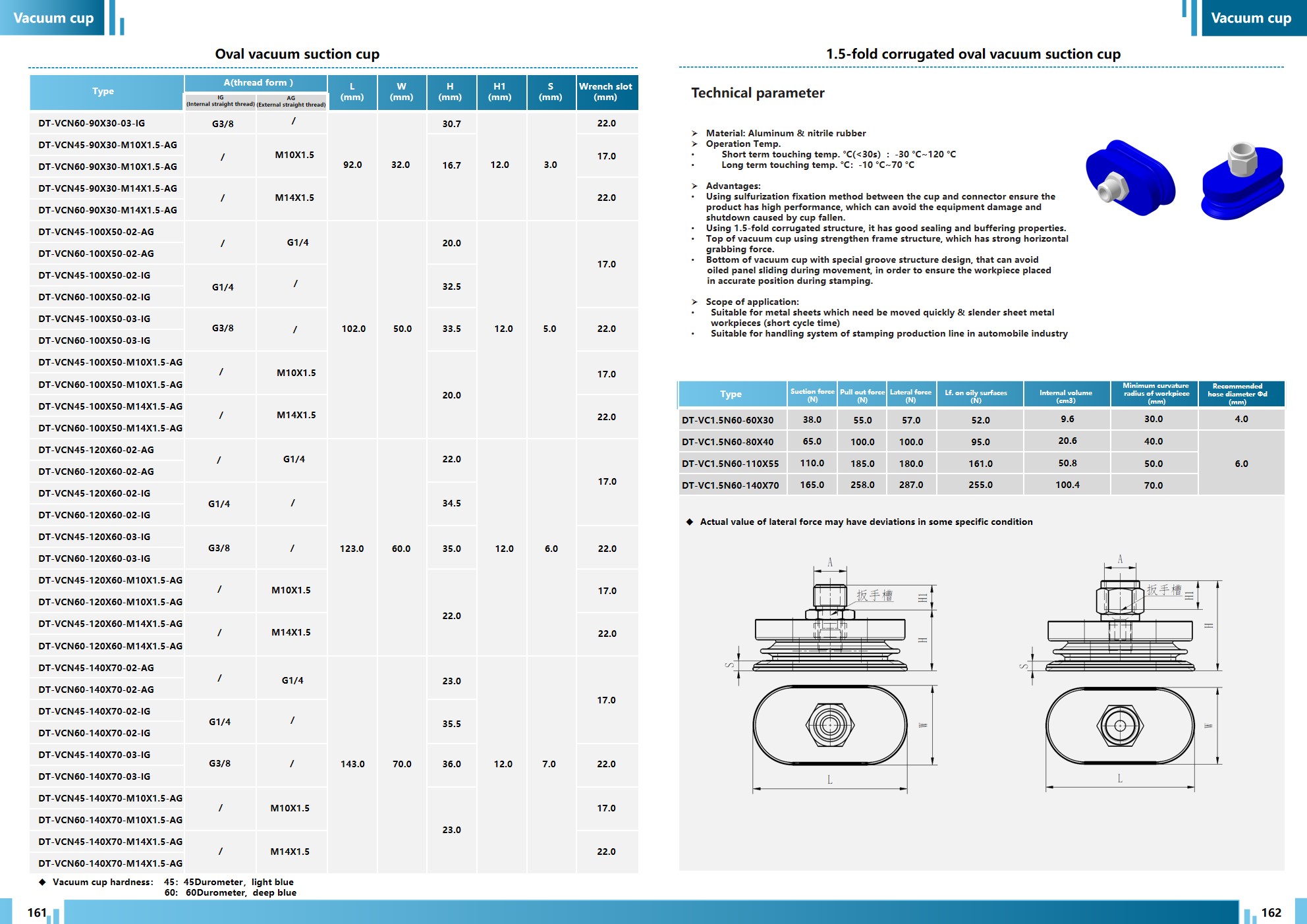

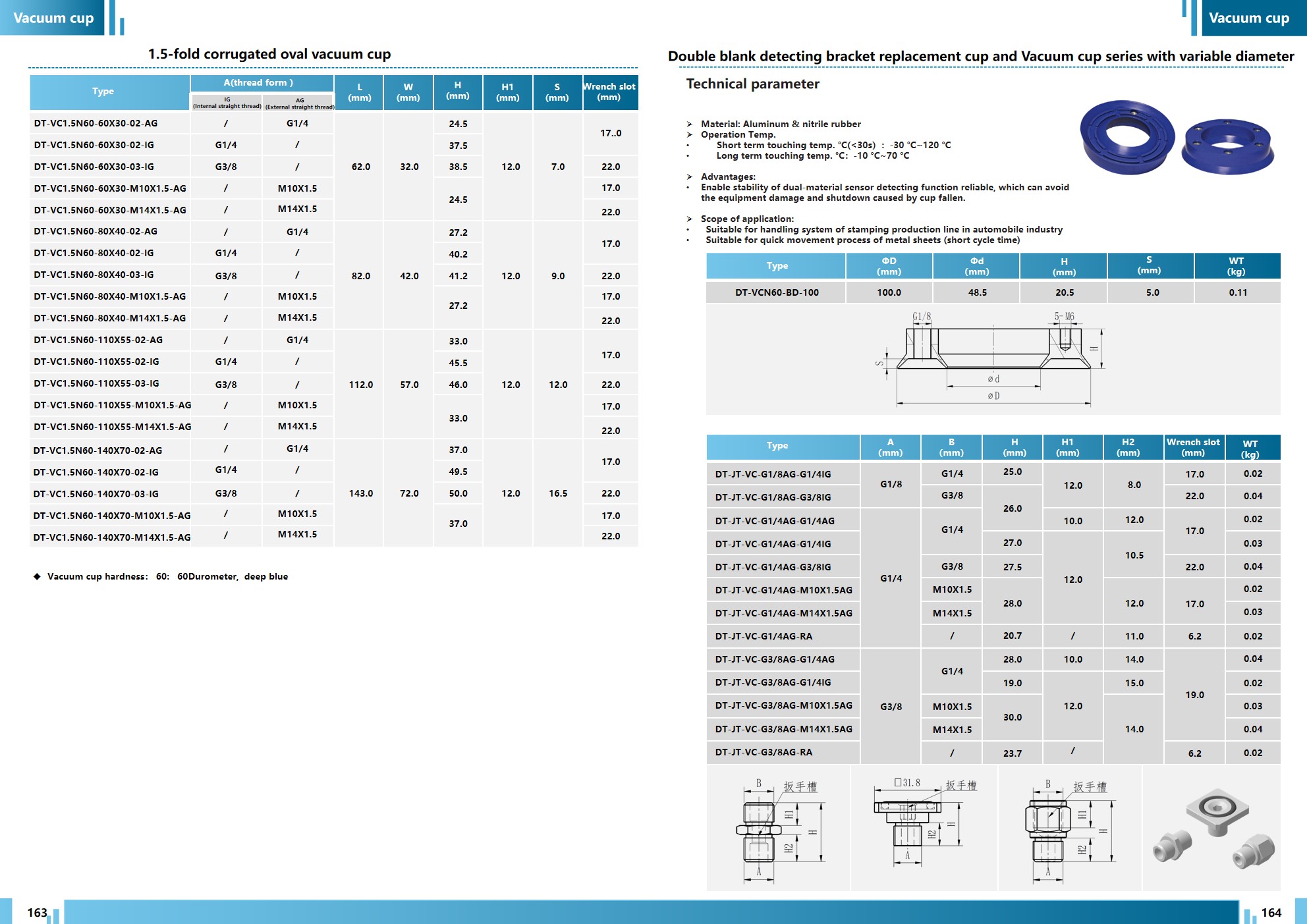

Adopted Materials:Aluminum & Nitrile Rubber

Product Advantages:

① Internal large-area support structure effectively increases the friction between the suction cup and the workpiece.

②The vacuum suction cup and connector are designed as an integrated unit, offering high strength performance and preventing damage to equipment and downtime caused by the vacuum suction cup coming loose.

.

③Vacuum suction cups are available in a variety of connection types.

④ Metal sheet metal parts with oily surfaces and slight curvature that can be transported.

用于CNC&机床加工时,上下料的搬运。