DT - Needle Suction Cup

In the wave of industrial automation, our needle-punched suction cup products have become a key tool for many companies to optimize production processes and improve efficiency thanks to their outstanding performance, injecting strong momentum into the automation upgrade of various industries.

一. Carefully selected materials lay a reliable foundation

Materials form the foundation of product performance, and our needle-punched suction cups demonstrate professionalism and rigor in material selection. The combination of aluminum and POM (polyoxymethylene) offers exceptional structural strength, effectively withstanding external impacts in industrial environments, while also providing excellent heat dissipation. This ensures that even during prolonged continuous operation, performance is not compromised by heat buildup. POM, a high-performance engineering plastic, inherently possesses wear-resistant properties, significantly reducing friction wear on components such as steel needles during operation. This extends the product's service life, ensuring the needle-type suction cup remains stable and reliable in complex operating conditions, thereby safeguarding long-term efficient production.

二. Wide compatibility with operating conditions to meet a variety of challenges

Industrial environments vary greatly, with complex pressure and temperature conditions. The working pressure range of this needle-type suction cup is 3 bar to 7 bar, enabling it to adapt and operate stably in both precision electronics workshops with relatively stable pressure and large-scale mechanical processing production lines with fluctuating pressure, without the need for additional complex pressure control equipment, thereby reducing production support costs. In terms of temperature adaptation, its operating range of 5°C to 60°C allows it to maintain performance seamlessly in cold northern winter workshops or high-temperature southern summer production lines, confidently tackling extreme environmental challenges and ensuring production continuity.

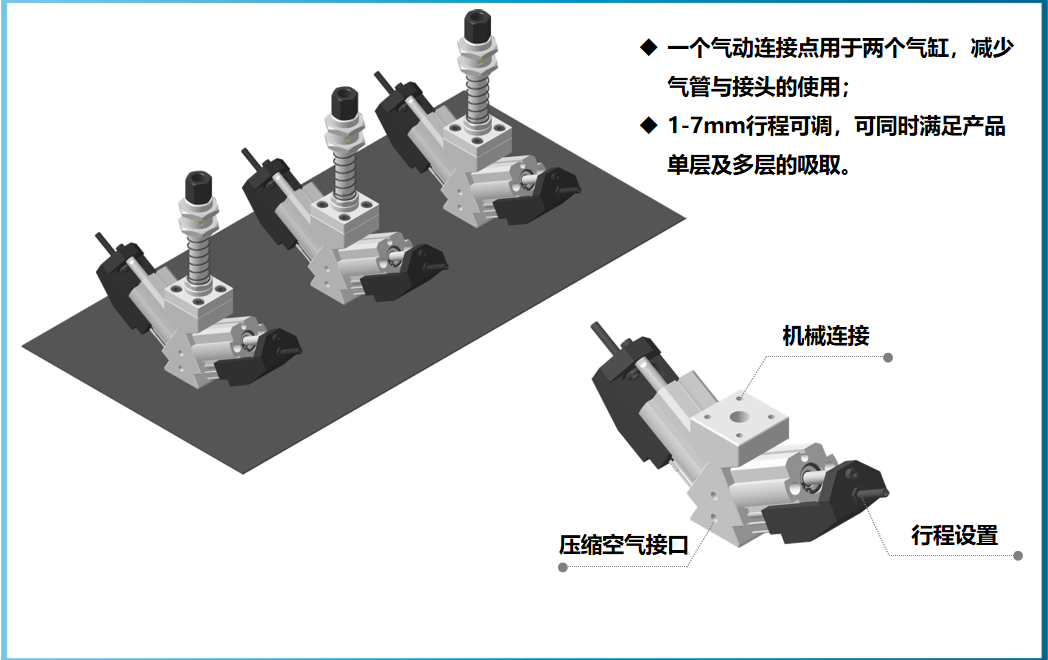

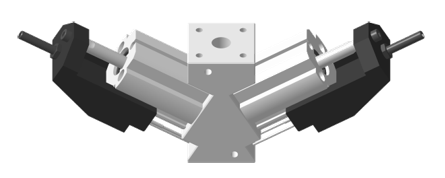

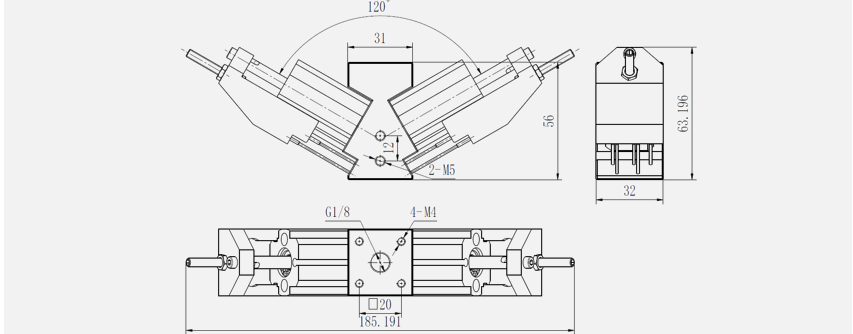

三. Modular design for convenient and efficient integration

To meet the demands of rapid integration in modern industrial automation, the needle-punched suction cup adopts a modular design. This design philosophy enables it to seamlessly integrate with various types of robotic arms without the need for cumbersome customization modifications. When upgrading production lines or constructing new facilities, companies can quickly integrate it into their existing automation systems, significantly reducing commissioning cycles and lowering the technical complexity of integration for personnel. From installation to operational deployment, the process is streamlined and efficient, helping businesses optimize production layouts at lower costs and in shorter timeframes, thereby accelerating their automation transformation efforts.

四. Precise performance, empowering precision manufacturing

In the precision-critical stages of industrial production, performance accuracy is of paramount importance. This product features precise control of the steel needle stroke, maintained at 7mm, combined with a stable 60N load. In automated operations, it enables precise needle-punch marking of materials; in material handling scenarios, it reliably performs positioning and gripping actions, ensuring that every operational step is executed with precision and accuracy. This precise performance streamlines production processes, effectively reducing defect rates caused by operational deviations, enhancing product quality, and providing robust support for enterprises to establish high-quality production lines.

Our needle suction cup products, with their superior materials, wide range of working conditions, convenient integration, and precise performance, have become indispensable and highly efficient “pioneers” in industrial automation production. They deeply meet the needs of enterprises to reduce costs, improve efficiency, and enhance quality, continuously driving various industries to accelerate their progress in the automation field, helping enterprises strengthen their core competitiveness, and embrace the production changes of the Industry 4.0 era.